The CHME Laboratory provides hands on instruction in the areas of instrumentation, transport phenomena, control systems, data collection and analysis, process safety, and unit operations.

Vapor/Liquid Equilibrium (CHME 323L)

|

Armfield TH3 Saturation Pressure rig

Description: In this experiment, students are introduced to the fundamental principles of thermodynamics. Experiments begin with basic concepts such as temperature and pressure measurement followed by introduction to the relationships between these concepts as well further study into the first and second laws of thermodynamics, the principles of reversibility, entropy, enthalpy, and more.

Linear and Radial Heat Conduction (CHME 323L)

Armfield Models HT10XC, HT11C, and HT12C

|

|

Description: This experiment consists of two separate but related parts. In one of them, students measure the thermal conductivity in the radial direction of a disk of stainless steel. Heat is applied to the center of the disk while the edge is cooled by flowing water. Students set the flowrate of cooling water and the power level of the heater to obtain a steady-state condition, and they measure temperatures at several positions along the radial direction from the center of the disk to the edge using thermocouples embedded in the metal and read with a control unit.

In the other part of the experiment, students measure the thermal conductivity in the axial direction of three different metals (aluminum, brass, stainless steel) of cylindrical shape. Similarly to the radial heat conduction set-up, thermocouples arranged along the lengths of the metals provide temperature data to a control unit.

The control unit is connected to a computer where all data is collected in spreadsheet form and is used by the students to calculate the various thermal conductivities, who then compare them to literature values.

Thermocouple/Viscosity Study (CHME 323L)

|

|

Cannon Model 2020 Viscometer

Description: This experiment consists of two parts. In the first, students construct a Type J or Type K thermocouple using the appropriate wire materials and a small welder. They then calibrate this thermocouple by immersing it in water and measuring its voltage as a function of temperature as measured by a traditional mercury thermometer. Then, in the second part of the experiment, with their calibration curve in hand, students measure the effect of temperature on the viscosity of two common vegetable oils and compare their findings to literature data.

Heat Exchange (CHME 324L)

|

|

Armfield HT33

Description: Two heat exchanger configurations are available. The shell and tube exchanger consists of several tubes in parallel enclosed in a cylindrical shell. Heat is transferred between one fluid flowing through the tubes and another fluid flowing through the cylindrical shell around the tubes. This exchanger demonstrates liquid-to-liquid heat transfer in a 1-7 shell and tube heat exchanger (one shell and seven tubes with two transverse baffles in the shell).

|

|

Armfield HT36

Description: The extended tubular heat exchanger consists of two concentric (coaxial) tubes carrying the hot and cold fluids. The tubes are separated into sections to reduce the overall length and to allow the temperature to be measured at points along both fluid streams.

Analysis of Centrifugal Pumps, Valve Coefficients, and Piping (CHME 323L)

|

Custom unit manufactured by Unit Ops, Inc.

Description: This apparatus consists of an array of piping, pumps, valves, flow meters, and pressure gauges that permit the pumping of water from a storage tank through several combinations of pumps and valves and back to the storage tank. Students measure pump efficiencies, friction losses in fittings, and valve coefficients.

Study of Fixed and Fluidized Bed Columns (CHME 324L)

|

Edibon Computer Controlled Fixed and Fluidized Bed Unit

Description: Students study the behavior of vertical glass columns filled to various levels with glass microspheres of different sizes. Pressure drops, effect of microsphere size, and conditions which lead to bed fluidization are studied for columns for which both air and water are used as the fluid medium.

Batch Reaction Engineering (CHME 324L)

|

A variety of reaction configurations are available.

Description: CSTR – The apparatus consists of a small stirred-tank reactor with inlet and outlet flows controlled by peristaltic pumps. The tank is water-jacketed for temperature control with heated water supplied by an adjacent thermostatic-contolled water bath. Reactant streams are pre-heated in this bath as well. The reaction studied is the neutralization of crystal violet by sodium hydroxide, a reaction that can be followed by monitoring the changing color of the solution, which goes from deep purple to clear as the reaction proceeds. The color change is followed by making periodic withdrawals of reactor solution samples and measuring their absorbance with a uv/visible spectrophotometer. For a continuous reactor such as this one, rather than following the reaction to completion, it is followed until steady-state (no further change in absorbance) is achieved. Batch mode operation is also possible.

Plug-Flow Reactor: A small-scale plug-flow reactor (Armfield CEY unit) demonstrates both the flow patter characterization and steady-state conversion in a tubular reactor with axial dispersion. Reaction progress can be followed by either color change or conductivity measurements, depending on the reaction under study.

Laminar Flow Reactor: Similar to the plug-flow reactor described above, this unit (Armfield CEZ) demonstrates flow-pattern characterization and steady-state conversion in a tubular reactor operated under laminar flow conditions.

Gas Absorption Using a Packed Column (CHME 423L)

|

|

Description : This experiment consists of two parts. In the first, students study the behavior of a 4.5-foot high, 6-inch diameter glass column filled with ceramic burl saddles. Water enters from the top while air or another gas enters at the bottom. Visual observations are used to determine column behavior as well as those circumstances that lead to flooding. Air is used as the gas for this. In the second part of the experiment, carbon dioxide is mixed with air to achieve a 5 volume percent concentration of CO 2, and students measure the degree of CO 2 absorption into the water as a function of gas and liquid flowrates. Carbon dioxide concentrations are measured by titration of exit stream water samples with sodium hydroxide solution.

Distillation Column (CHME 423L)

|

|

handmade by artisan glassware craftsman

The plated glass distillation column is operated in batch mode. It has twenty sieve trays, a reboiler, a condenser, and a reflux ratio controller. Temperatures are measured along the length of the column, and samples may be taken at several points as well. In the experiment, students study the separation of methanol from water. Condensate compositions are determined by measuring the mixture’s refractive index.

Plug-Flow Reaction Engineering (423L)

|

In this experiment, the reaction of sodium hydroxide and ethyl acetate in the presence of an indicator is studied in a vertically-oriented, plug-flow reactor (glass tube) packed with 3 mm glass beads to maintain axial dispersion and good flow distribution. Reaction progress is followed both visually by observing indicator color change along the reactor length and by measurement of conductivity, which is then converted to concentration with appropriate calibration curves. Conversion can be varied by varying reactant flowrates and by varying temperature. With the results, the reaction rate constant and Arrhenius parameters (pre-exponential factor and activation energy) can be calculated and compared with literature values.

Laminar Flow Reaction Engineering (423L)

|

This experiment is similar in set-up to the plug-flow system in that it consists of a vertically-oriented glass tube, but with no packing. There is no mixing either radially or axially. It is considered an ideal tubular reactor. As with the plug-flow system, reaction progress is followed both visually and by conductivity measurement

Basic Process Control (CHME 424L)

|

|

PCT40 Basic Process Control Unit

Description: The process control laboratory capability includes three independent but complementary process units (Armfield PCT50, PCT51, and PCT53) providing an introduction to the fundamental principles of process control engineering. Each is a water-based process and provides a demonstration of a different single PID loop using level, flow, or pressure as the measured variable.

Each of the units is independently operable and controlled by software installed on a dedicated PC with a USB connection. The effect of making changes to the system or to the controller configuration can be investigated by applying repeatable disturbances to the process, demonstrating the need for correct matching of system characteristics and controller settings. The software allows all appropriate measurements and controller settings to be displayed continuously and recorded for later analysis.

In addition to the units above, the laboratory also has an Amfield PCT40 process control unit. This unit is also computer-controlled and is used in this course to demonstrate temperature control as a complement to the level, flow, and pressure control systems described above.

Together, these four units give the students a complete exposure to process control.

- PCT50 Issue 5

|

|

|

- PCT 51 Issue 2

|

|

|

- PCT 53 Issue 4

|

|

|

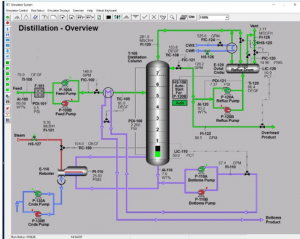

Distillation Simulation (CHME 424L)

|

Description: A commercially-available distillation simulation program provided by Simulation Solutions, Inc., demonstrates all aspects of the distillation of a pentane/hexane mixture in a seven-tray distillation column. Start-up, operation, shut-down, upset analysis, error analysis, troubleshooting, and optimization are covered. Students operate the simulation program following instructions in the student handbook which accompanies the software.

Continuous Improvement through Modernization:

Fall 2017 – With Western Refining gift funding, Armfield heat exchanger, process control, and reactor units were added to the lab. The fifty year old concentric pipe heat exchanger was retired.

Spring 2017 – With funding provided by student technology fees, a commercial distillation column simulator was purchased and used in the lab for the first time.

Fall 2014 – With ER&R funds, the CHME Department secured funding for Dr. Dan Gulino to renovate and re-plumb the Department’s treasured glass distillation column. As the photos above show, Dr. Gulino has had an enjoyable time converting what was destined to becoming a museum piece back into a fully-functional, automated, and computer-controlled unit operations laboratory experiment.

Summer 2014 – The laboratory has benefited from a series of modernizations funded by Western Refining (WNR). In the past two years, the lab has received new flooring and paint on the walls. The most recent $20K gift from WNR will permit a renovation of adjacent space, increasing the usable area in the lab by 1,029 sqft, a 67% increase in available space.

Manuals

- CEXC Issue 9

- CEY Issue 6

- CEZ Issue 6

- HT30XC Issue 19

- Brewmation Manual